Overview Description

35+ years experience: 10K+ sets high precision injection molds

High Precision Injection Mold Development

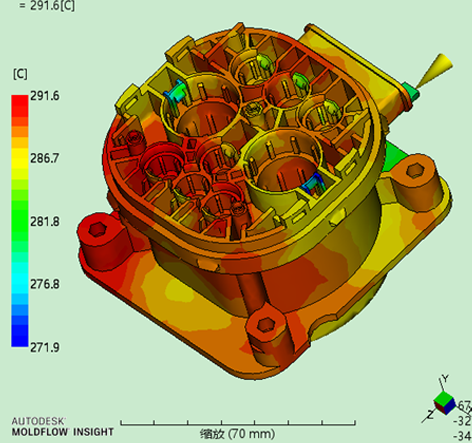

Experienced designers use Pro/E and Creo software for mold design. At the early stage of the project, a feasibility study will be conducted based on customer requirements, followed by a professional DFM analysis supported by our extensive experience and mold flow simulation. These efforts help reduce production risks, enhance production and quality stability, lower costs, and improve customer competitiveness.

- + product aide design

- + Pro/e /Creo

- + DFM Feasbility Manufacture Plan

- + reel to reel molding

- + insert molding

- + 2 color shot molding+ professional project management

1000 new molds design capacity per year

High Precision Injection Mold Fabrication

+ Grinding machine

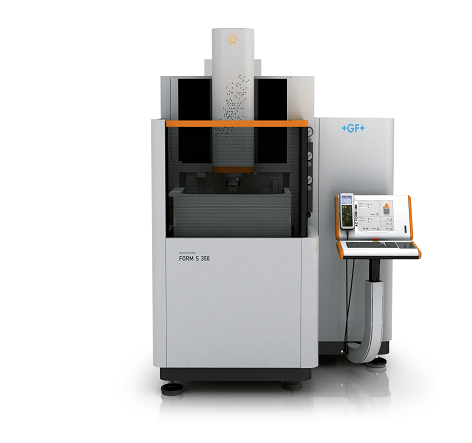

+ W/C EDM machine

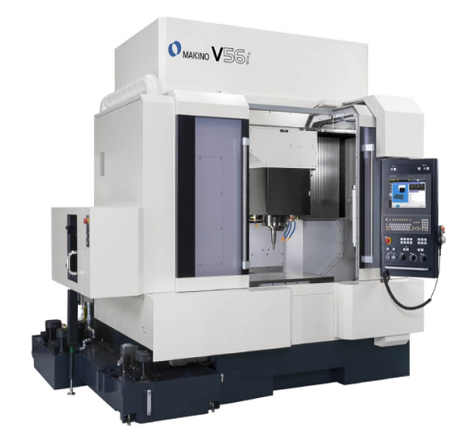

+ CNC machine

+ EDM Machine

+ CMM

1000 new molds manufacture capacity per year

High Precision Injection Molding

Polygon group is equipped with over 300 molding machines ranging from 5T to 250T, including horizontal, vertical, rotary, two-color shot, and cleanroom types, which can meet diverse production requirements. Meanwhile, the production management system (MOS) is implemented to achieve digitalization, paperless operation, and partial automation, ensuring that every part meets customer delivery requirements

- + Horizontal molding + Rotary Molding

- + 2 Color shot molding + LSR Molding

- + Vertical molding + Clean room molding

- + Insert molding + Micro Molding

- + reel to reel molding

- + MOS molding production management system

95%+ punctual delivery rate; 3 Billions+ parts production per year